SNACKS PROCESS SYSTEMS

Introducing the Pina Engineering Pvt. Ltd. Whole Snacks Processing Plant, a comprehensive solution

designed to revolutionize snack production and meet the growing demands of the snack

industry. With cutting-edge technology and a focus on efficiency, our processing plant

offers a complete range of equipment and systems to streamline snack manufacturing from

start to finish.

The Pina Engineering Pvt. Ltd. Whole Snacks Processing Plant boasts a range of technical

characteristics and advantages:

- Machine

- Sheeting Machine

- Dough Mixer

- Washing Line

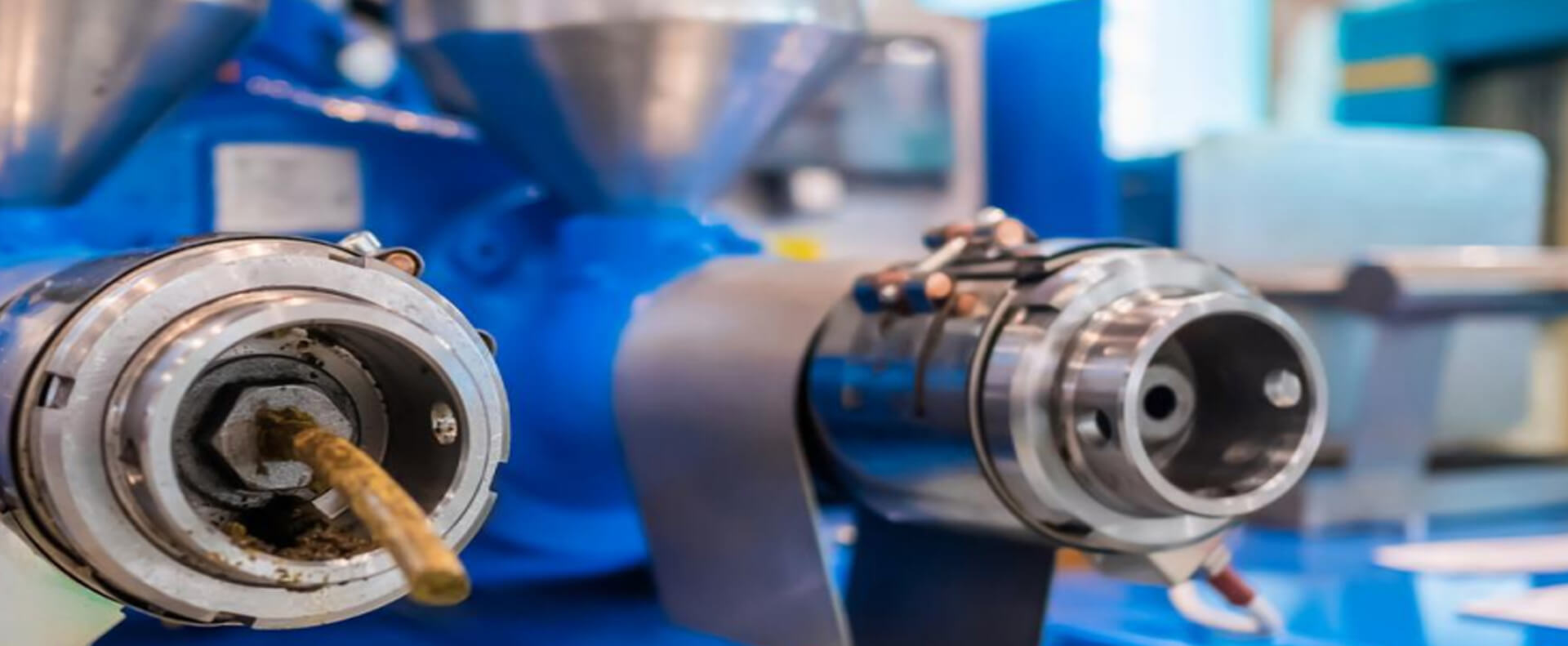

- Extruder

- Blancher

- Electroporation

- Vacuum Frying | Continuous Fryer

- Conveying Oven

- Slicing Machine

- Applications

- Potato Chips & Crisps

- Extruded Snacks

- Nuts & Seeds

- Popcorn

- Healthy Snacks

- Dehydration

Technical Characteristics and Advantages:

Versatile Processing Capabilities:

Our plant is equipped with a wide array of processing equipment, allowing for the production of various snacks such as chips, extruded snacks, nuts, popcorn, and more. From raw material preparation to final packaging, we have you covered.

Advanced Automation:

Our processing plant features state-of-the-art automation systems, ensuring precise control, optimal production efficiency, and consistent product quality. Automated processes minimize human intervention, reduce errors, and increase overall productivity.

Customizable Production Lines:

We understand that each snack manufacturer has unique requirements. Our processing plant offers customizable production lines, allowing you to tailor the equipment layout, capacities, and processes to meet your specific needs.

Efficient Raw Material Handling:

Our plant includes advanced systems for raw material handling, such as sorting, washing, drying, and blending. These systems ensure consistent quality and cleanliness of ingredients, contributing to the production of high-quality snacks.

Superior Processing Equipment:

We provide a wide range of cutting-edge processing equipment, including fryers, ovens, extruders, seasoning machines, and packaging systems. Our equipment is designed for efficiency, precision, and durability, resulting in consistent and flavorful snacks.

Quality Control and Monitoring:

Our processing plant incorporates advanced quality control and monitoring systems to ensure that snacks meet the highest standards. These systems allow for real-time monitoring of critical parameters, such as temperature, moisture, and production speed, ensuring consistent product quality and adherence to specifications.

Innovate Snack Production:

Embrace the future of snack manufacturing with the Pina Engineering Pvt. Ltd. Whole Snacks Processing Plant. Revolutionize your processes, expand your product portfolio, and meet consumer demands with efficiency and quality. Contact us today to embark on a journey of snack innovation with Pina Engineering Pvt. Ltd.

.png)